About Leather, a guide to Leather for Leathercrafters and those new to Leathercrafting

About Leather

There is a lot to learn about leather and hopefully this small brochure will help you understand a little more about buying leather.

Will my leather be perfect?

"Will my hide/panel be perfect?", this a great question and the answer is a bit complex and relies on some understanding different leather cuts and finishing you purchase.

Leather comes from animals that over their lifetime can develop scratches, bite marks, branding, stretch marks and more. Even the highest graded leather will show defects more/less depending on the cut of leather and its finishing process. Blemishes are only bites, scratches, holes, cuts.

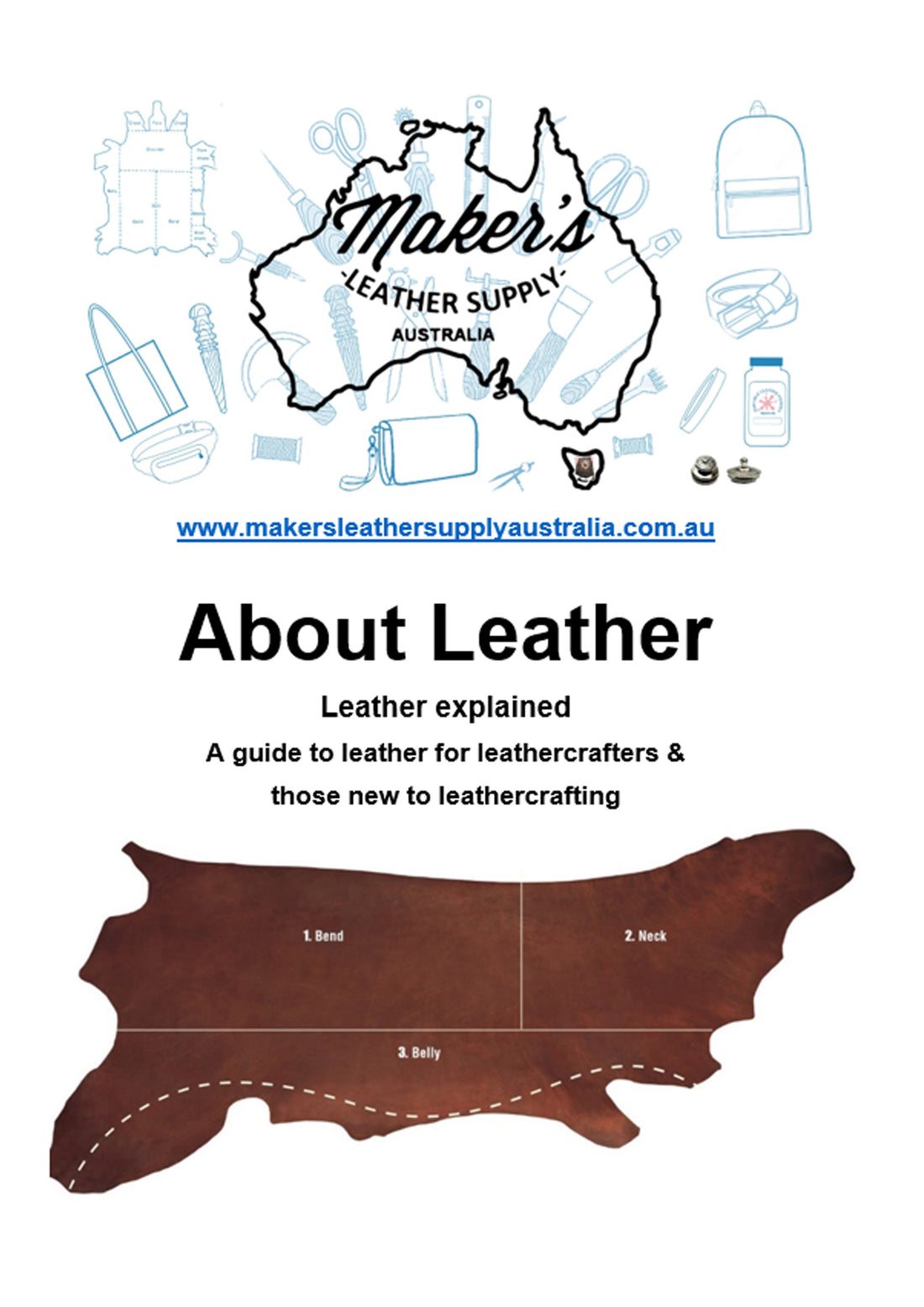

Cuts of leather

Certain cuts of leather have higher yield and contain less defects. Here are a few cuts to better understand

1. Whole Hide

This contains the entire hide (Legs, Belly, Back, Neck and more) The whole hides has it all good and bad. The center areas are the cleanest and offer the highest yield. The belly is considered waste in many manufacturing settings due to its loose grain and being a bit stretchy. Certain articles better hide stretch marks in the belly area but others don't. Wrinkles can be found in the neck, back and belly area. When purchasing whole hides you get more opportunity to work around defects and cut nice large pieces.

2. Side

The side is whole hide cut in half along the back. Similar good and bad as whole hides. In this case you only have 1 belly, 1/2 neck and 1/2 back to deal with. The benefit to sides are they are larger and give you flexibility in where you cut pieces to optimize your yield.

3. Double Shoulder

The Double shoulder is like a whole hide but with no belly or butt area. These are really nice cuts and give a higher yield than sides. You still have the back are and neck area that can have wrinkles but the pieces are usually really nice in general

4. The Bend

- Thickest and firmest part of hide, thicker than thre rest of hide.

- Best used where minimum stretch, firmness and durability are essential.

- Fibre's are thicker

5. The Neck

- Good quality, but may have more blemishes than the bend.

- Neck area may have more barbed wire scratches and natural fat wrinkles. Tanners make special efforts to smooth out the wrinkles, but depending on the age of the animal, they may still be visible.

- Has as much tensile strength (ability to stretch without tearing) as the bend, sometimes more.

6. The Back(Made up of the Bend and Neck)

- Very good quality.

- Best buy for products which require length and durability with least amount of waste (e.g. reins, stirrup leathers, leashes, etc.).

- Includes the areas of the bend and neck.

7. The Belly

- Fibers are softer and looser than in other parts of the side.

- Often considered the “waste” section of the side – but it can be very useful for a variety of purposes.

- Sewn to the back of a bend, neck or middle, it provides comfort and has all the strength of the piece it is sewn to.

Note: Tanners trim the side and cut some of the fleshy leg pockets out, but some may remain. The dotted line indicates the area that may need to be trimmed, depending on the side.

Coloration

Each batch can have varying shades of color.. Chrome Tanned leathers are more consistent in color, Veg Tanned leathers patina over time and change color.

Recommendations

There is some skill and experience involved in working with leather and how to cut a hide up. We have a few recommendations

- If you are making large items (bags) that need perfect large pieces please contact us about helping select the right hide that meets your specifications. We can also send a picture or video.

- The best way to get the most out of a leather hide is to work blemishes into less visible areas of a project. Also the natural variation in leather can be beautiful and showcased. Japanese crafters are masters in showing the beauty of natural blemishes in Embracing this can make your products feel more handcrafted and not something mass produced.

Leather measurement

Whole hides are usually measured in square metres (m²) and square feet (f²). The average size of a full cattle hide is approximately 55 square feet or 4.5 to 5.5 square metres. Average size of sides or half hide (side) is approximately 25 square feet.

Types of leather

The main methods of tanning animal skins are Vegetable and Chrome tanning.

Vegetable Tanning

Refers to the tannage, or method of tanning the cowhide into leather. It’s called “vegetable” because of the natural materials used in the tanning process like tree bark.

Since vegetable tanning is a natural process, it’s also ecofriendly. Vegetable tanning or veg tan as it’s sometimes called, is one of the oldest methods of tanning known to man. It has literally been around for centuries.

Veg tan leather has a lovely warm and silky feel and is used by leathercrafters to stamp, tool, emboss, paint, dye or stain. Veg tan is typically firm and is preferred by saddle makers. It has a rich patina that gets better with age and use. This patina look is sought after and guarantees that projects made with veg tan will improve for years to come.

Chrome tanned leather.

Leather tanned in Chromium Salts (this is a much faster process than Vegetable Tanning)

Chrome-tanning, uses an industrial method for modern machinery and mass-production. The tanning process utilizes mineral salts (chemicals and metals) like chromium and mercury instead of plant tannins and re-introduces shelf-stable oils for flex and suppleness.

90% of leather is chrome-tanned these days, mostly because chrome tanning can take as little as one day. The resulting leather is soft with a fabric-like drape, and can be dyed in any color because its natural hue is bleached out in the process (called wet blues). The shoe and fashion industries use this kind of leather the most. Because of its fast processing time, it is less expensive than vegetable-tanned leather.

Chrome leather is used for shoe uppers, soft handbags, clothing and upholstery.

The method produces a strong, lightweight and very flexible leather. Chrome leather is sold by the square foot or by the metre. In upholstery leathers, the entire skin is sold as large areas are required. For shoe leather, the hide is cut in half down the length of the spine. Smaller animals such as calf, kid and pig are sold as whole skins.

After the skin is tanned, it is dyed and the top surface (grain) finished to create different finishes such as suede, nubuck & patent.

Other sorts of Leather

Crazy Horse Leather

Crazy Horse Leather is NOT made from horses. Crazy Horse is a leather industry term, it can vary between different tanneries. It is usually full grain chrome tanned leather with a soft hand made by applying special purpose waxes to a full grain surface. These waxes are melted and migrated under frictional heat. As a result when the leather surface is rubbed the color of the rubbed portion changes, and doesn’t change immediately. This is called pull up..

Combination Tanned Leather

Combination tanned leather is tanned using a combination of the synthetic chrome and natural vegetable tanning processes.

Oil Tanned Leather

Chrome tanned leather treated with oils.

Oil tan is type of chrome tan leather best known for its "pull up." Oil tan leather is heavily treated with oils that darken the color of the leather. When the leather is creased or scratched, the oil redistributes to reveal a lighter color. That lighter color is called "pull up". Pull up is lauded for making abrasions and wear look more appealing, making it perfect for rustic projects and projects that emphasize creases and/or folds.

|

Types of Leather |

Qualities |

Used For |

|

Cow |

Tight grain, strong and supple, variable in thickness and versatile |

Footwear uppers and for general purpose |

|

Calf |

Finer textured with a silky firm surface, lightweight and expensive |

Fine footwear, handbags |

|

Kangaroo |

Strong, lightweight and thin. 10 times tensile strength of Cowhide |

Whipmaking, braiding, clothing, shoes |

|

Goat |

Pronounced grain. Thin and lightweight. Can be made into fine suede. Also known as Indian kips. |

Bags, purses, wallets, book bindings |

|

Kid |

Fine and delicate, usually has a glaze finish. |

Purses, wallets, linings for shoes and bags. Can be used as an upper for fine sandals if strengthened. |

|

Sheep |

With or without wool usually has a suede finish. Loose fibres make this a squashy soft material. |

Slippers, moccasins, and clothing. Chamois wash leather is made from split suede sheepskin |

|

Deer |

Strong but very supple and soft to touch |

Traditionally used by Natiive Americans for moccasins, bags and clothing |

|

Pig |

Thin, hard wearing. Distinctive triple hair grain on surface |

Linings for footwear and leather goods. Insoles for shoes. Purses and wallets |

|

Exotics - Snake, Lizard, Ostrich and Crocodile |

Various qualities |

Used for handbags and footwear. |